Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

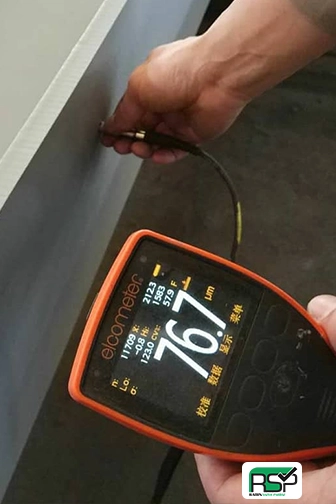

NDT stands for Non-Destructive Testing, which refers to a set of testing methods used to evaluate materials, components, and structures without causing damage. The primary goal of NDT is to detect defects, cracks, voids, and other internal or surface imperfections that may affect performance and service life.

NDT stands for Non-Destructive Testing.

Rabin Sazeh Pardaz offers complete supervision and inspection services for your project with the highest quality, on-time delivery, and minimal cost.

At RABIN SAZEH PARDAZ, we are designers and executors of industrial projects. Relying on technical expertise, we manage projects from design to equipment procurement. Our goal is to provide efficient and reliable engineering solutions for various industries.